FLYWOO Waterproof Invisible Spray

Check out all of our Flywoo products!

Protect your sensitive FPV drone electronics with the next generation of conformal coating: FLYWOO’s X30 Waterproof Invisible Spray. Moving far beyond traditional methods, this superhydrophobic formula creates a highly durable, water-repellent barrier that offers superior protection while also enhancing thermal performance. It’s the ultimate solution for any FPV drone builder looking to safeguard their investment against the elements.

Superior Superhydrophobic Protection

Inspired by the lotus leaf, the X30 spray forms a surface with a water contact angle greater than 160°, causing moisture to bead up and roll off instantly. This provides a robust shield against rain, splashes, morning dew, salt spray, and corrosion. In demanding salt spray and wet/dry cycle tests, this coating has been shown to significantly outperform traditional conformal paints, ensuring your FPV drone parts stay protected for longer.

Protects Without Trapping Heat

A major advantage of the Flywoo X30 is its excellent heat dissipation. Unlike thick urethane or silicone coatings that can trap heat and cause components to run hotter, this ultra-thin (20-50µm) inorganic-organic composite coating has impressive thermal conductivity. This means it protects your ESC, VTX, and flight controller without compromising their ability to cool themselves, enhancing overall system reliability.

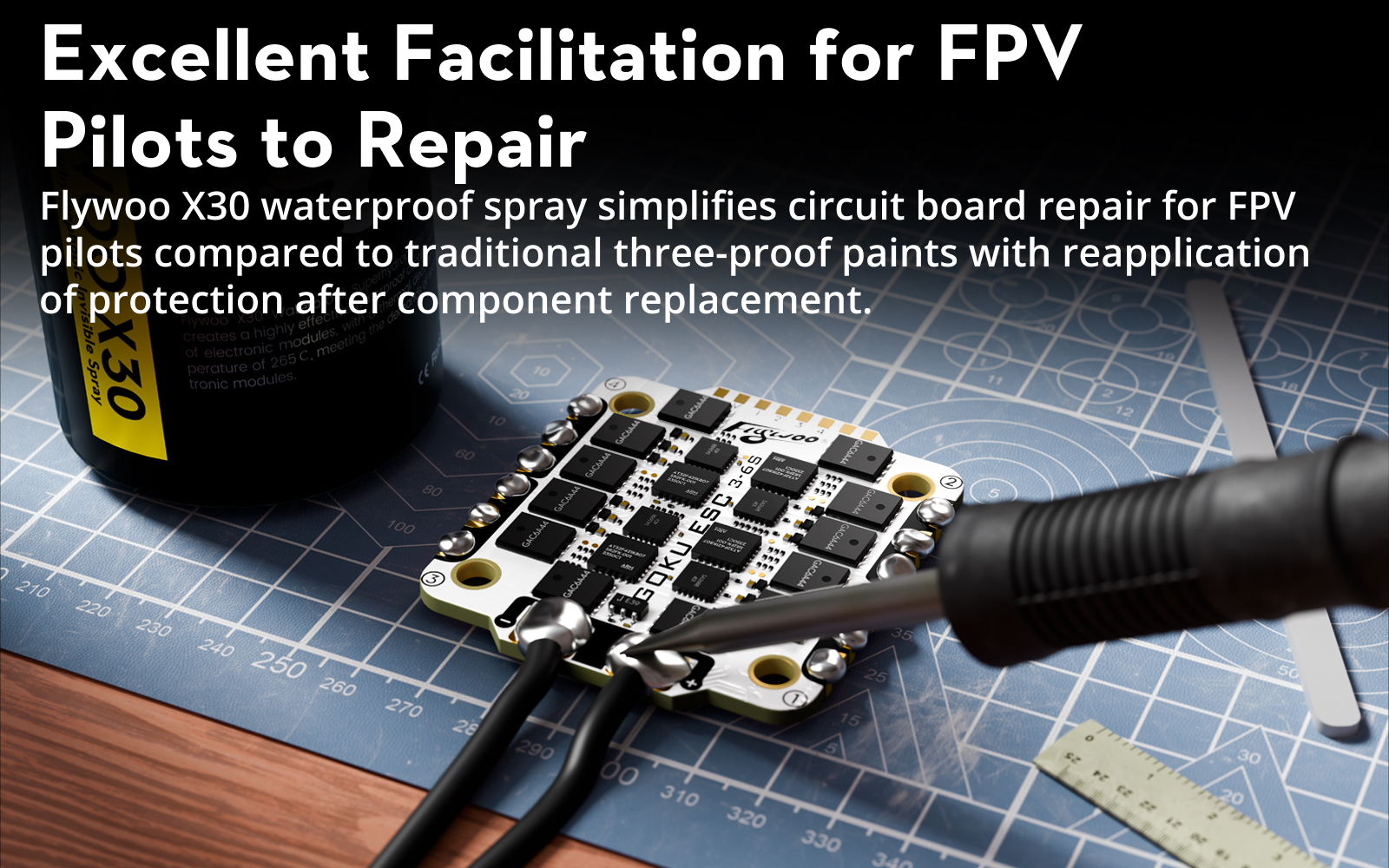

Simplify Your Builds & Repairs

The spray-on application is incredibly simple and fast, forming an effective coating in just minutes. A key benefit for builders is its ease of use during repairs. Unlike thick, rubbery coatings that must be painstakingly scraped off, you can simply solder through the thin X30 layer to replace a component, and then easily re-apply a new protective coat over the repaired area.

Key Advantages Over Traditional Coatings

- Better Waterproofing: Higher water repellency with a 160° contact angle.

- Enhanced Durability: Outperforms traditional coatings in salt spray and wet/dry cycle tests.

- Superior Heat Dissipation: Allows electronics to run cooler thanks to high thermal conductivity.

- Thinner Application: Provides full protection in a thinner, lighter layer (20-50µm).

- Safer Formula: Environmentally friendly and does not contain the harmful substances often found in other coatings.

Application Instructions

- Thoroughly clean the surface of the circuit board to remove any dust, grease, or flux residue.

- Shake the can well to ensure the liquid is uniform.

- Apply a light, even coat. For best results, apply 2-3 coats, allowing 2-3 minutes of drying time between each layer.

- The surface will be dry to the touch in minutes and ready for use.

Note: While this spray can be used on camera lenses, it may reduce image quality. It provides excellent water resistance but is not intended for full, prolonged submersion of a powered-on FPV drone.

What’s in the Box?

- 1x Flywoo X30 Waterproof Superhydrophobic Invisible Spray